What are California Temporary K-Rail Specifications?

The California Department of Transportation (CalTrans) outlines specifications regarding the proper dimensions of temporary railing (type K) barriers, including general notes, typical panel design, opening details and alternative head details.

California Temporary K-Rail General Notes

For end treatment, layout and crash cushions, where needed, see Project Plans or Special Provisions.

All 3-1/2” gaps at removable panels should be backed at the base with #8 x 10” dowel or 1” pins at each side of the joint.

Where the offset distance from the exposed edge of the deck to the closest edge of the temporary railing is less than 2’-0”, attach each panel to the deck slab with 1” diameter threaded rods (a total of four per panel) inserted through the slotted holes of the panel and bond in drilled holes 6” deep in the deck slabs.

California Temporary K-Rail Design for a Typical Panel

Temporary barriers in California should be K-Rail of 19’-10” precast length (20’-0” laying length) with:

- Four 4” lifting holes, two set at either end of the panel and two set on the outside of the lifting slots

- Two 2’ lifting slots, each set 3’ away from the center of the panel

- Slotted holes for threaded rods

- Each panel should be placed at least 2’ from the edge of the deck or excavated slope.

- Each panel should weigh 3.9 tons.

California K-Rail Section A-A

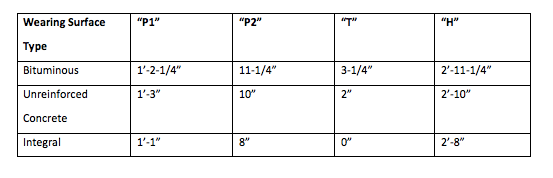

From an end view, section A-A panels should conform to the following:

- Height: 2”-8”

- Bottom width: 2’-0”

- Top width: 6”

- Slope: R=10”; starts 1” from ground line

- Height of the bottom slope: 10”

- Height of the top slope: 1’-7”

- Break point: 10” from the pavement or ground line

- Vertical reveal: 1”

- Symmetrical in nature

- ¾” top edge chamfer

California K-Rail Section G-G

Section G-G is for concrete pavement and includes the following specifications:

- Alternate detail, 1” pins 2’-0” long driven into existing AC or HMA.

- Include a #8 x 10” dowel, drill and bond in a hole 5” deep within 1’ of removeable panel.

- Traffic should occur on the opposite side of the dowel only.

California K-Rail Typical Opening Detail

When placing K-rails, there should be a minimum of 100’ to the next opening (if required). Paint the ends of removable panels and adjacent panel sections with black paint, with a max gap of 3-1/2” between each of these two panels.

California Alternative Head Detail

Alternative heads should include a bar that is 1-1/4” by 2’-2” long, and a 3” diameter plate that is 3/8” thick.

This blog post is an interpretation of specifications by the California Department of Transportation (CalTrans). Please consult with CalTrans' most recent requirements for definitive information.

BUY AND SELL WITH EIFFEL TRADING

The Eiffel Trading marketplace allows contractors to sell their unneeded assets, including various types of used and surplus precast barrier wall including k-rail barrier, low profile barrier, various DOT spec barriers, and much more. Additionally, our construction material inventory also ranges to include used h pile beams, used steel plates, crane mats, and much more.

All of our listings are constantly being updated, but if you don’t see what you’re looking for, create a wanted listing for free.

Ready to sell your used heavy equipment or construction material? List your products today for free on Eiffel Trading’s online marketplace.

If you have any questions or would like additional information, please call us at 1-800-541-7998 or email sales@eiffeltrading.com.