What are Maine Temporary Concrete Barrier Specifications?

The Maine Department of Transportation outlines specifications regarding the proper dimensions for temporary concrete barriers, including general notes, plan view details, elevation details, and more.

Maine Temporary Concrete Barrier General Notes

The Maine Department of Transportation’s general instructions are as follows:

- Alternate barrier designs may be submitted for approval by the Resident.

- Form a ¾” chamfer or radius on all exposed edges.

- Galvanize connectors after forming. Connectors may be completely galvanized.

- Galvanize the connector pin assembly after fabrication. Burr the threads on the pin after installing the nut.

- The reinforcement shown is primarily for the impact performance of the barrier. Additional reinforcement may be advisable for handling the barrier and for ensuring its integrity over its service life.

- When serving the additional function of channelizing traffic, the barrier should be supplemented by standard delineators, channelizing devices or pavement markings.

- Barrier delineators should be bi-directional with a minimum effective reflective area of 8.0” squared as approved by the Resident. The reflector should preferably be of Methyl Methacrylate, and the housing of Acrylonitrile Butadiene Styrene. As an alternative, reflectors may be mounted on the top of the barrier.

Maine Temporary Concrete Barrier Specifications

Maine barriers should conform to the following specifications, according to the Maine Department of Transportation:

Plan View

Barriers measure 10’-0” long and include a bottom connector on the right side and a top connector on the left side. Each connector extends out from the edge of the barrier by 2-1/2”.

Elevation View

Barriers include two lifting slots, which are set 3’-4” from the outside edges of the barrier and 3’-4” apart from each other. The lifting slots measure 4” wide.

Barriers include two #6 rebars x 8’-0” and a #6 rebar x 9’-0”. On the left side, the upper bar protrudes from the edge of the barrier at a distance of 6” when measured from the top of the barrier; the lower bar is set 1’-6” below the upper bar. On the right side, the upper bar protrudes from the edge of the barrier at a distance of 8” when measured from the top of the barrier; the lower bar is set 1’-6” below the upper bar.

End View

There is one barrier delineator per side on every third barrier.

The bottom of the barrier measures 2’-0” wide and the top of the barrier measures 6” wide. There is a 1’-0” v-notch at the bottom of the barrier and a 3” vertical reveal. The height of the barrier is 2’-8”. R=10. The height of the lower slope is 10” and the height of the upper slope is 1’-7”. The width of the upper slops is 4”.

Connecting Pin

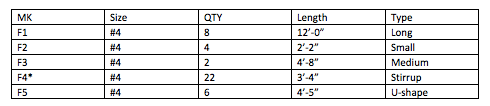

Each connecting pin includes a hex nut with a steel washer at the top. Connecting pins measure 2’-0” long and 1-1/8” wide. There is a ¼” diameter hole at the bottom of the connecting pin for the cotter pin. The threading at the top of the connecting pin measures 2”.

Cotter Pin Detail

Cotter pins measure 1-1/2” (minimum) and are 3/16” SAE Standard.

Washer Details

Washers are made of 3/16” thick galvanized steel. Their inner diameter measures 1” and their outer diameter measures 2-1/8”.

Top Connector

Top connectors are made of #6 rebar (typ.) and have a minimum galvanized length of 6”. R=1-1/2”.

Bottom Connector

Bottom connectors are made of #6 rebar (typ.) and have a minimum galvanized length of 6”. R=1-1/2”. The open end of the connector measures 9” wide. The v-section of the connector measures 1’-8” long.

Weld Detail

The bead is to be at least flush when welded (typ.), and should be no less than 5/16” in diameter.

This blog post is an interpretation of specifications by the Maine Department of Transportation. Please consult with Maine DOT's most recent requirements for definitive information.

BUY AND SELL WITH EIFFEL TRADING

Eiffel Trading’s robust barrier wall inventory ranges from used f shape barrier wall, to used single slope barrier wall, and all types in between. Furthermore, we market a wide variety of other construction materials, including used h pile beams, used trestle, and much more.

All of our listings are constantly being updated, but if you don’t see what you’re looking for, create a wanted listing for free.

Ready to sell your used heavy equipment or construction material? List your products today for free on Eiffel Trading’s online marketplace.

If you have any questions or would like additional information, please call us at 1-800-541-7998 or email sales@eiffeltrading.com.