The Texas Department of Transportation outlines specifications regarding the proper dimensions for Type 2 precast concrete traffic barrier (PCTB), including general notes, plan view details, elevation view details, and more.

Texas Low Profile Precast Concrete Barrier (Type 2) General Notes

The Texas Department of Transportation’s general instructions are as follows:

- Welded wire reinforcement (WWR) is not an option for Type 2 barriers.

- Type 2 barriers should be used as an end treatment for the Type 1 barrier segments, when applicable.

- The end treatment can be used without the anchor pins in locations that can accommodate approximately four feet of lateral displacement of the end treatment. The use of non-pinned end treatment does not affect the performance or the deflection of the low profile barrier system.

- The anchor pins are all the same length and are to be driven flush with the top of the Type 2 barrier surface.

- The bends in the H3 and H1 bars are slight, no formal bend is necessary.

- The Type 2 low profile barrier wall segments must be lifted from the rear first, to prevent cracking of sloped sections.

Texas Low Profile Precast Concrete Barrier (Type 2) Specifications

Barriers should conform to the following specifications, according to the Texas Department of Transportation.

Plan View

Type 2 barriers measure 20’-0” long, 26” wide on their widest end and 14” wide on their shortest end. The widest end of the barrier stretches for 5’-0” before it begins to taper. In this section, 30” away from the end of the barrier, there is a drain slot and a drain hole. Just before the barrier begins to taper, there are 2” nominal diameter lifting pipes, which are set 4’-0” from the barrier’s end.

There are seven 1-3/4” diameter steel anchoring pipes running through the tapered section of the barrier, which are each spaced 24” apart.

Elevation View

The barrier includes H1, H2 and H3 bars, as well as bars V1 to V16. Bars V1 to V14 run vertically through the barrier’s tapered end and are each spaced 12” apart from each other. On the left (non-tapered) side of the barrier, there is a drain slot and a series of horizontal reinforcement bars running through the barrier.

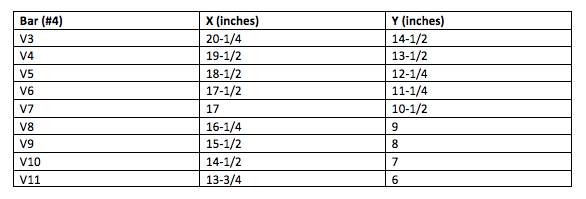

Bar Dimensions

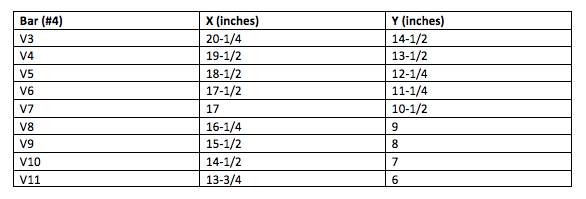

Bars V3 to V14 vary in size, as shown in the table below.

V1 Bars

Each barrier includes five V1 Bars. This rebar is a square shaped rebar with one unconnected, overlapping corner. The rebar measures 21” long and 13-1/2” wide. The overlapping ends measure 5” each.

V2 Bars

Each barrier includes 12 V2 Bars. This rebar is a U-shaped rebar with three sides, plus one open end. The bottom of the U measures 21” long, and each arm of the U measures 13-1/2” long. The open end of the rebar measures 12” across. The ends of each arm of the U is bent, and this bent section measures 4-1/2” and 10-1/4”.

H2 Bars

Each barrier includes four H2 Bars. This is a U-shaped bar. Each arm of the bar measures 41” long, the open end of the bar measures 22-1/2” wide, and there is a 6” diameter bending pin on both corners.

Remaining V Bars

The remaining bars include the following dimensions:

- V12 = 13” x 4-3/4”

- V13 = 12-1/4” x 3-3/4”

- V14 = 11-1/2” x 2-3/4”

- V15 = 10-3/4”

- V16 = 10”

- H3 = 16’-4”

- H1 = 19’ – 8”

ASTM A36 Connection Bolts and Plate Washer

Nuts, hex nuts and washers should all be galvanized.

Connection bolts measure 26” long. They are 1-1/4” in diameter and include a thread that is a minimum of 4” long. Hex nuts are Grade 5. The plate washer measures 5” x 10” x 3/8” and includes two holes, through which the connection bolts will be secured.

This blog post is an interpretation of specifications by the Texas Department of Transportation (TxDOT). Please consult with TxDOT's most recent requirements for definitive information.

BUY AND SELL WITH EIFFEL TRADING

Eiffel Trading has an extensive precast barrier wall inventory, including used low profile barrier wall, used single slope barrier wall, used f-shape barrier wall, and much more. Furthermore, our inventory ranges to include various equipment items, such as concrete formwork, pile drivers, and so on.

All of our listings are constantly being updated, but if you don’t see what you’re looking for, create a wanted listing for free.

Ready to sell your used heavy equipment or construction material? List your products today for free on Eiffel Trading’s online marketplace.

If you have any questions or would like additional information, please call us at 1-800-541-7998 or email sales@eiffeltrading.com.