What are the West Virginia DOT Jersey Barrier Specifications?

The West Virginia Department of Transportation outlines specifications regarding the proper dimensions of six inch Jersey shape concrete barrier walls, including general notes, end view specifications, plan view specifications, elevation details, connector details and plate details.

West Virginia Jersey Barrier General Notes and Specifications

Jersey barriers in West Virginia must conform to the following specifications:

Materials

- Concrete: Class AA concrete 5,000 PSI minimum compressive strength

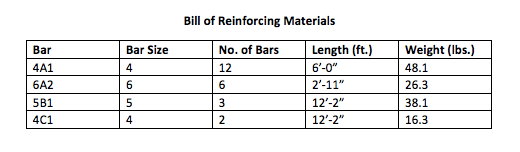

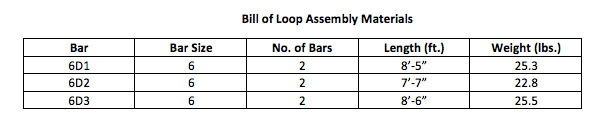

- Reinforcing: ASTM A-708 Grade 80; rebars welded to steel connector plates; ASTM A-185 welded wire fabric

- Steel: ASTM A-36

Tolerance

- Connector location plus or minus 1/16”

- Width of connector plus or minus 1/32”

- Connector plate size + 1/8”

- Barrier length + ¼”

Welding

All welding should be in accordance with American Welding Society structural welding codes

Design

FHWA approved shape. J-J hooks should be accepted by FHWA as a crash tested and operational design for use on all federal highway projects.

Installation

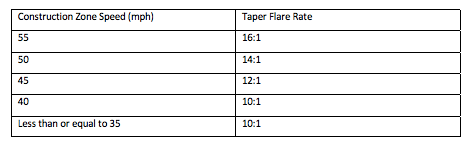

Barriers should be installed at maximum separation in order to minimize barrier deflection upon impact.

There is a maximum separation of 1-1/2”.

West Virginia Jersey Barrier End View Specifications

From an end view, West Virginia Jersey barriers should conform to the following:

- Bottom width: 2’-0”

- Top width: 8”

- Height of the bottom slope: 1”-1”

- Height of the top slope: 10”

- Break point: 10” from the pavement or ground line

- Vertical reveal: 3”

West Virginia Jersey Barrier Plan View Specifications

Each Jersey barrier panel in West Virginia should conform to the following dimensions and include the following features:

- Width: 2’-0”

- Length: 12’-0”

- ¾” chamfer at each end

- 3/8” plastic insert with NC thread

- Rebar and mesh running through the center of each panel

West Virginia Jersey Barrier Elevation Details

Each Jersey barrier panel in West Virginia should conform to the following dimensions and include the following features:

- Height: 2’-8”

- Length: 12’-0”

- One drainage slot located at the center of the panel

- 6 x 6 mesh that is 1’-6” wide

- ASTM A-708 bars welded to each end connector

- 1’-0” space between the welded bars

- 10” between each end of the connector plate and the ends of the panel

- The end of the barrier should be sloped back from the top of the connector to top of the barrier, with ½” of space created through the slope

- 3/8” plastic insert with NC thread

- Rebar and mesh running through the center of each panel

West Virginia Jersey Barrier Positive Connector and Connector Plate Details

Positive connectors and connector plates should conform to the following dimensions and include the following features:

Positive Connectors

- Two interlocking connector plates

- 2 x 2 x 3/18 angle

- ASTM A-708 grade 80 bars

Connector Plates

- 3/8” connector plate thickness

- ¾” between the center of the connector plate hook and the top of the plate

- ASTM A-708 grade 80 bars

*Please note that this blog post is an interpretation of West Virginia Department of Transportation's specifications. Please consult with WV DOT's most recent requirements for definitive information.

BUY AND SELL WITH EIFFEL TRADING

Between used jersey barrier wall, used k-rail barrier wall, used f-shape barrier wall, and more, Eiffel Trading’s online marketplace has it all! In addition, our construction equipment inventory includes used foundation equipment, used cranes, and much more.

All of our listings are constantly being updated, but if you don’t see what you’re looking for, create a wanted listing for free.

Ready to sell your used heavy equipment or construction material? List your products today for free on Eiffel Trading’s online marketplace.

If you have any questions or would like additional information, please call us at 1-800-541-7998 or email sales@eiffeltrading.com.