Sheet Pile Application: Cutoff Wall

A cutoff wall is constructed to keep groundwater out of excavation areas and ultimately to eliminate the need for dewatering using pumping and other methods. Building a cutoff wall typically entails the creation of an impermeable barrier that surrounds the perimeter of the job site. Cutoff walls are most commonly vertical and driven into a deep layer of earth (bedrock or clay) to secure them in place. Sheet pile is a top choice for cut off walls. In addition to being made of sheet piles, cutoff walls may also be made of grout barriers, slurry trench walls, mix-in-place barriers, concrete diaphragm walls, or bored pile walls. Artificial ground freezing may also be used to create a cutoff wall.

MATERIALS

The materials used to construct a cutoff wall depend on both the conditions of the environment in the affected area and the specific needs of a project. Factors like ground conditions, the needed depth of the wall, the needed height of the wall, and whether or not the wall will be a permanent structure all come into play when deciding the proper materials and method.

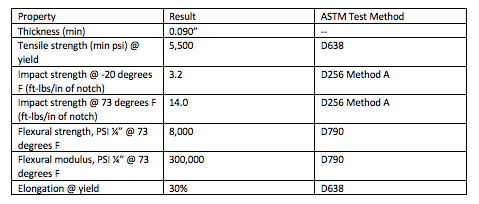

Both steel and plastic sheet piles can be used to construct cutoff walls, but the use of steel is more common. The use of plastic sheet piles is a fairly new development, and plastic is still not considered the most effective and durable option. Both steel and plastic piles used for cutoff walls are ordinarily around 18 inches in width and between 30 to 50 feet in length. Plastic sheet piles should be thick and rigid.

OPERATIONS

Steel sheet pile cutoff walls are a popular choice because they are relatively easy and quick to install and don’t necessitate excavation before their installation. Additionally, they are quite durable. During the construction of a cutoff wall, interlocking steel sheet piles are driven into the ground individually. They are often driven using a vibratory hammer to the required depth. If a greater amount of depth is needed, piles can be welded to those already driven into the ground. In the case of the use of sealable joints, all debris and soil are flushed from joint cavities after which a sealant is added within the cavity.

PROPER CLOSURE

Cutoff walls made of sheet pile sometimes present issues involving leakage through their interlocks. Minimizing the width of openings in interlocks and the insertion of sealant into interlocks can prevent leakage. Additionally, as a cutoff wall is being built, crew members should pay special attention to prevent any damage to sheet piles or interlocks. Neglecting to do so may result in vulnerabilities in the cutoff wall structure that ultimately lead to leakage.

Proper closure of sheet piles is integral to the successful build of a cutoff wall. Adequate closure involves control of the inclination of sheet piles on each side of their gap which does not exceed around .2 percent. In order to ensure proper closure and decrease the likelihood of deformation of the cutoff wall, methods such as tack welding and skip welding of the pile may be necessary.

In addition to being used for cutoff walls, sheet pile walls are common in a number of different dewatering capacities to form structural walls. For instance, in dam applications, they may be used to prevent horizontal seepage of water through strata that is permeable or semi-permeable.

BUY AND SELL WITH EIFFEL TRADING

Eiffel Trading’s online marketplace inventory ranges widely to include a wide variety of sheet pile, barrier wall, HDPE pipe, and more options. Furthermore, our marine equipment inventory ranges from sectional barges, to winches, to chain pullers, and everything in between.

All of our listings are constantly being updated, but if you don’t see what you’re looking for, create a wanted listing for free.

Ready to sell your used heavy equipment or construction material? List your products today for free on Eiffel Trading’s online marketplace.

If you have any questions or would like additional information, please call us at 1-800-541-7998 or email sales@eiffeltrading.com.