What are the Kansas Concrete Barrier Specifications?

The Kansas Department of Transportation outlines specifications regarding the requirements for installing permanent cast in place concrete barriers and temporary precast concrete barriers, including materials required, construction requirements, measurement information and payment information.

Kansas Permanent Cast-In-Place Concrete Barrier Specifications

The Kansas Department of Transportation’s specifications are as follows:

Materials

Provide materials that comply with the Contract Documents and DIVISIONS 1000 - 2500. The Engineer should visually inspect the completed installation before making the final acceptance.

Construction

Construct the cast-in-place concrete safety barrier as shown in the Contract Documents and according to DIVISION 700. Place median filler material as indicated in the Contract Documents.

Measurements

The Engineer will measure cast-in-place concrete safety barriers by the linear foot along the centerline of the barrier.

Kansas Temporary Precast Concrete Barrier Specifications

The Kansas Department of Transportation’s specifications are as follows:

Materials

Provide certification (prepared by the Manufacturer or Contractor) that the temporary precast concrete safety barrier complies with the requirements on the Contract Document. The temporary precast concrete safety barrier can be either new or used. The Engineer will accept the temporary precast concrete safety barrier upon acceptance of the provided certification. Acceptance will also be granted after the Engineer does a visual inspection of the installed temporary precast concrete safety barrier.

Construction

Install and remove the precast concrete safety barrier as required. Do not use temporary precast concrete safety barriers that are damaged or deteriorated.

Erect the temporary precast concrete safety barrier as shown in the Contract Documents. The temporary precast concrete safety barrier will remain the property of the Contractor, unless shown otherwise in the Contract Documents.

If the Contract Documents require installation only, transport from the designated stockpile, install and return the temporary precast concrete safety barrier to the designated location. Relocate the temporary precast concrete safety barrier as shown in the Contract Documents, or as directed by the Engineer.

Remove and replace all sections of temporary precast concrete safety barrier that have been damaged during or after placement. Remove, clean or replace any temporary precast concrete safety barriers (including barrier delineators) that have deteriorated past the point of use.

Measurement and Payment

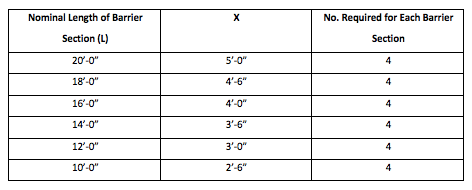

The Engineer will measure the precast concrete safety barriers by the linear foot (number of sections times the nominal section length). A precast concrete safety barrier transition section (regardless of actual length) will be measured as a nominal section length of temporary precast concrete safety barrier.

The quantity of precast concrete safety barriers measured for payment is the maximum quantity required on the project at any one time, plus any replacement sections measured for payment.

Each section of the temporary precast concrete safety barrier will be measured for payment if it’s used on the project. Sections of the temporary precast concrete safety barrier that are used to replace sections that have been damaged by traffic while in use will also be measured for payment. These will be paid as “Concrete Safety Barrier” so long as they are used on the project.

When provided by the Contractor, sections of temporary precast concrete safety barrier used to replace deteriorated sections or sections damaged through negligence of the Contractor are not measured for payment.

When stage construction requires that the precast concrete safety barrier be moved from its initial position to an alternate position, the Engineer will measure the relocated barrier by the linear foot (which again is the number of sections times the nominal section length). The barrier will be measured for payment in each relocated position that the barrier is placed; it will be paid as “Concrete Safety Barrier.”

If the stage construction requires that the barrier be removed from the project to a storage location, and returned to the project during a subsequent construction stage, each movement of the barrier will be considered a relocation.

Removal of the precast concrete safety barrier, when no longer required on the project, is not measured for separate payment.

This blog post is an interpretation of specifications by the Kansas Department of Transportation. Please consult with Kansas DOT's most recent requirements for definitive information.

BUY AND SELL WITH EIFFEL TRADING

Eiffel Trading works with a wide variety of heavy civil and marine contractors to market and sell their surplus and used materials, including all types of barrier wall, such as f-shape barrier wall, low profile barrier wall, single slope barrier wall, and more. Furthermore, our range of used equipment includes used tug boats, used shoring equipment, and much more.

All of our listings are constantly being updated, but if you don’t see what you’re looking for, create a wanted listing for free.

Ready to sell your used heavy equipment or construction material? List your products today for free on Eiffel Trading’s online marketplace.

If you have any questions or would like additional information, please call us at 1-800-541-7998 or email sales@eiffeltrading.com.