What are the Idaho Precast Concrete Barrier Specifications?

The Idaho Transportation Department outlines specifications regarding the proper dimensions for precast concrete barriers, including general notes, plan details, and pin details.

Idaho Precast Concrete Barrier Notes

The Idaho Transportation Department’s general instructions are as follows:

- The precast concrete barrier described is a MASH Test level 3 longitudinal barrier system. The barrier uses the F-shape cross section.

- Precast using class 50AF concrete. Chamfer top, bottom and edges at ¾”. Provide a 2” minimum concrete cover over reinforcing steel. A 2” white PVC sleeve may be used to form the lifting hole. If used, leave the PVC sleeve in place.

- Pin connect barrier units. Precast concrete barriers may be angled approximately 7 degrees at connections.

- Provide the calculated length of need upstream from hazards and provide at least three precast concrete barrier segments downstream of hazards. Do not install fewer than six barrier segments.

- The precast concrete barrier can be installed free-standing or anchor pinned to pavement.

a. If free-standing, anchor the two barrier segments nearest the end (not counting a concrete barrier termina) with anchor pins as described in note 5b.

b. If anchor pinned, use two pins in each barrier segments installed on concrete pavement and use three pins in each barrier segment installed on asphalt pavement. If anchor pinned in a median, install anchor pins on both sides of the barrier (four total on concrete pavement, six total on asphalt pavement). Pre-drill anchor pin holes in concrete pavement using the slot as a guide.

- When transitioning from freestanding to anchor pinned barrier, install one anchor pin in the slot of the last freestanding segment closest to the first anchor pinned segment.

- When transitioning from freestanding barrier to rigid barrier, such as cast in place concrete barrier or bridge rail, transition first to anchor pinned precast barrier, then to the rigid barrier. Cut off the end loops of the last segment of the precast barrier in the F-shape to single slope transition.

- When transitioning from freestanding barrier to W-beam guardrail, anchor pin the last three precast concrete barrier segments and connect to a guardrail transition. Chamfer the last 3-1/2 inches of the barrier and drill give 1” diameter holes as shown.

- Flare the upstream end of the barrier in accordance with the concrete barrier shy-line offset and flare rate table.

- Terminate the barrier with a crashworthy end treatment or transition to another barrier system. Acceptable end treatments include tapering the barrier outside of the clear zone, transitioning to W-beam guardrail, a crash cushion, a precast concrete barrier terminal, or transition to a bridge rail or parapet. When connecting the F-shape precast concrete barrier to a New Jersey shape precast concrete barrier, use the F-shape to New Jersey shape transition.

Idaho Precast Concrete Barrier Plan Details

Precast concrete barriers in Idaho should conform to the following dimensions and include the following features, according to the Idaho Transportation Department’s specifications:

Elevation View

- Length: 12’-6”

- Two lifting slots that are each 12” long; each slot should be spaced 31-1/2” from the end of the barrier

- There should be three loop pins protruding from each side of the barrier

- On the left side of the barrier, the loop pins should be spaced as follows: 6” between ground and bottom loop pin; 4” between bottom loop pin and middle loop pin; 14” between middle loop pin and upper loop pin; 8” between upper loop pin and top of barrier; these measurements should be inverted for the loop pins on the right side of the barrier

Section A-A

- Bottom width: 24”

- Top width: 9-1/2”

- Height: 32”

- Bottom slope: 40 degree angle

- Break point: 10”

Section B-B

- Bottom width: 24”

- Top width: 9-1/2”

- Height: 32”

- Chamfer: ¾”

- 10” R

- Vertical reveal: 3”

Section C-C

- Bottom width: 24”

- Top width: 9-1/2”

- Height: 32”

- Chamfer: ¾”

- 10” R

- Bottom slope: 40 degree angle

- Vertical reveal: 3”

Idaho Precast Concrete Barrier Pin and Connector Details

Precast concrete barrier pins and connectors in Idaho should conform to the following dimensions and include the following features, according to the Idaho Transportation Department’s specifications:

Anchor Pins

Anchor pins should include be 48” long for asphalt and 21-1/4” long for concrete. Pins should include a 2” beveled end on one end, and a plate washer on the opposite end. Plate washers should be 4” x 4” wide, ½” thick and include a central hole that is 1-5/8” in diameter.

Connecting Pins

Connecting pins should measure 29” long with an additional 1” thread at one end and a tapered point at the other end. Connecting pins should measure 1” in diameter (ASTM A449). Pins should include a 2” diameter circular ASTM A572 washer at 1/8” thickness (minimum).

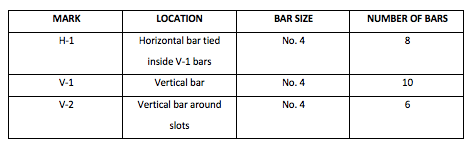

Idaho Reinforcing Steel Table

Reinforcing steel should conform to the following table, according to the Idaho Transportation Department’s specifications:

This blog post is an interpretation of specifications by the Idaho Department of Transportation. Please consult with Idaho DOT's most recent requirements for definitive information.

BUY AND SELL WITH EIFFEL TRADING

Eiffel Trading’s online marketplace displays a wide selection of new and used barrier wall types, including but not limited to single slope barrier wall, jersey barrier wall, and more. Furthermore, our marine equipment inventory ranges from used push boats, to used crew boats, to used marine accessories, and everything in between.

All of our listings are constantly being updated, but if you don’t see what you’re looking for, create a wanted listing for free.

Ready to sell your used heavy equipment or construction material? List your products today for free on Eiffel Trading’s online marketplace.

If you have any questions or would like additional information, please call us at 1-800-541-7998 or email sales@eiffeltrading.com.