What are Oklahoma Concrete Longitudinal Barrier Specifications?

The Oklahoma Department of Transportation outlines specifications regarding the proper dimensions for concrete barriers, including general notes, section details, and more.

Oklahoma Concrete Longitudinal Barrier General Notes

The Oklahoma Department of Transportation’s general instructions are as follows:

- All construction and material requirements should be in accordance with the 2009 ODOT Standard Specifications.

- Price bids should include payment for materials, labor, pipe sleeves, expansion joints, and all incidentals necessary to complete the installation.

- For details of longitudinal barrier mounted light pole bases and installations, see the current version of Traffic Standard BMFI-2.

- Longitudinal barriers should be measured for payment as continuous barriers. Payment for light pole footings are to be included in other items of work.

- When longitudinal barriers are placed on flexible bases or surfacing, contraction joints or chamfers are required at a maximum of 20 feet C/C spacing and expansion joints are required at a maximum of 200 feet C/C spacing. When the longitudinal barrier is place on P.C. concrete surfacing, the joints should match the joints on the rigid surfacing. Saw-cut joints within 10 hours of barrier placement.

- When longitudinal barriers are constructed or exist prior to construction of adjacent shoulders or overlays, the shoulder layering should not alter the original traffic side geometry of the longitudinal barrier.

- Delineator units should be placed on median barriers according to the current version of traffic STD. DU1-1. All cost of installation should be included in the unite price bid of traffic pay item barrier delineators.

- An alternate design (including precast) concrete longitudinal barrier, meeting NCHRP 350 or MASH requirements, may be used when approved by the engineer.

- Walls of inlets may be made of brick masonry or of Class A concrete, to the same dimension. Price of I-beam, frames and grates should be included in the price bid of inlet. Welding should be per current AWS D1.1 structural welding code.

Oklahoma Concrete Longitudinal Barrier Specifications

Oklahoma barriers should conform to the following specifications according to the Oklahoma Department of Transportation:

Section A-A

According to section A-A details, barriers should include a space of 2-1/2” below the normal gutter; a single opening distance of 3’-0”; and a double opening distance of 6’-0” (max).

Section B1-B1

Section B1-B1 details outline the longitudinal barrier (design 1). Section should be 3’-5” in length, with a 6” minimum clearance distance.

Section B2-B2

Section B2-B2 includes configurations for steel plates, flow line at the top of the grate, and longitudinal barrier (design 1). Each side of the section measures 3’-0” wide, with a top section measuring S6 x 12.5” x 5’-11-1/4”. The notes include instructions to see steel plate details for more information.

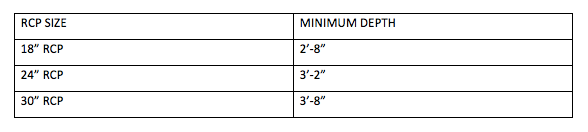

RCP size varies based on depth.

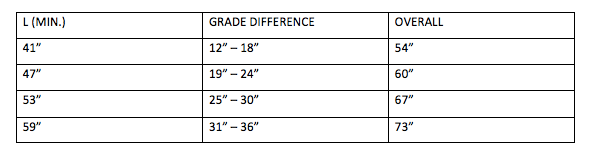

Bending Diagram

The bending diagram outlines measurements for Bar C (J-hook) at 10” C/C. The long-end length of the bar varies with differential grade (see chart below). The radius of the hook is 2-1/2”, the short end of the bar measures 6”, and the distance between the long end of the bar and the short end of the bar is 5”.

Bending Diagram Bars A & B

The #5 deformed reinforced bar has a radius of 2-3/4” (interior) and an exterior radius of 8” or 168 degrees. The length of bar A is 49-1/4” and the length of bar B is 36-1/2”.

Section C-C

According to section C-C details, transitions should be backfilled with sand. Barriers include a ½” expansion joint, #5 bars and a 4” conc. Div. strip (on bridge pier transition only).

Detail Expansion Joint

The barriers are filled with ¾” pre-molded expansion material. There is a ¾” chamfer on all edges and a 2” clearance (minimum) from reinforcing steel to the nearest face.

Section D-D

All vertical stirrup and horizontal reinforcing steel should overlap a minimum of 24” at splices and have a 2” clearance (minimum) from reinforcing steel to the nearest face.

There is a grade elevation of 1-1/2” (max.) permissible offset between grade elevations.

Des. 1 quantities / ft. are as follows:

- CONC. (CY) = 0.159

- STEEL (LBS) = 4.17

Plan of Delineator Placement

Delineators should be placed at 50’-0” centers along the top of median barrier; skew delineators 15 degrees to improve reflectivity.

This blog post is an interpretation of specifications by the Oklahoma Department of Transportation. Please consult with Oklahoma DOT's most recent requirements for definitive information.

BUY AND SELL WITH EIFFEL TRADING

Eiffel Trading’s barrier wall inventory is ever-changing, and includes a wide variety of barrier types, including single slope barrier, low profile barrier, jersey barrier, and more. Additionally, our construction equipment inventory ranges from used concrete formwork, to crawler drill rigs, and everything in between.

All of our listings are constantly being updated, but if you don’t see what you’re looking for, create a wanted listing for free.

Ready to sell your used heavy equipment or construction material? List your products today for free on Eiffel Trading’s online marketplace.

If you have any questions or would like additional information, please call us at 1-800-541-7998 or email sales@eiffeltrading.com.